In the categorie INTERLAYER you read about the different kinds of interlayers we can find on the market.

To understand what delamination means we first have to explain how glass is laminated.

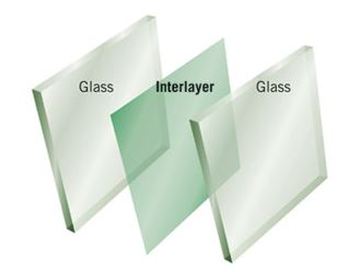

Laminated glass happens by melting one of several interlayers with several glass panels which are covered all over the surface of the glass panels. The interlayers can be translucent PVB's, colored Vanceva's, Saflex DG or Sentry Plus. Laminated glass is a composite end product which ads the properties of glass as the properties of the chosen interlayer.

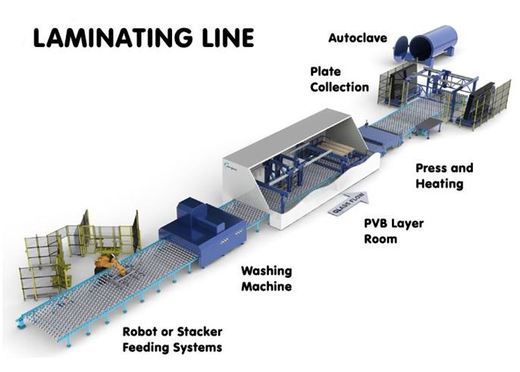

Laminated glass is produced through a rolling process, followed by a treatment in the autoclave.

Under high pressure & temperature the enclosed air bubbles ( between the glass panels & the interlayers) are extracted and the glass panels & interlayers are sealed in one translucent end product.

When glass breaks, the shattered glass sticks to the interlayers and using structural interlayers as Saflex DG & Sentry Plus the glass keeps its function as railing system.

Under high pressure & temperature the enclosed air bubbles ( between the glass panels & the interlayers) are extracted and the glass panels & interlayers are sealed in one translucent end product.

When glass breaks, the shattered glass sticks to the interlayers and using structural interlayers as Saflex DG & Sentry Plus the glass keeps its function as railing system.

What do they mean with 44.2, 88.DG41 or 1010.4 ?

The composition of laminated glass is indicated, in the glass sector, al follows ; the first figures state the amount and thickness of the used glass panels. The figure behind the dot reveals the amount ( not the thickness) of the interlayers.

In a 44.2 we have two glass panels of 4mm with two interlayers. ( interlayers can have a thickness of 0,38, 0,73, 1,14mm,...) of 0,38mm.

A 88.DG41 consists of two glass panels of 8mm and one Saflex DG41 interlayer of 0,76mm thickness. The total thickness of the glass panel is 2 X 8mm + 1 X 0,76mm = 16,76mm.

A 1010.4 ( commonly known as laminated & tempered version) consists of 2 glass panels of 10mm with 4 PVB's of 0,38mm. The total thickness of the glass panel is 2 X 10mm + 4 X 0,38mm = 21,52mm.

So what is delamination ?

The traditional PVB's can, in function of wheather circumstances and the way of laminating & polishing, sooner or later come in contact with moisture ( rain, dew, humidity). When this moisture finds its way between the PVB's and the glass panels there is a risk the adhesive properties of the PVB's would decrease in order to produce air bubbles on the edges of the glass panels. This phenomenon is called delamination.

|

How can this be prevented ? Two possibilities : A Delamination can be prevented by covering the edges of the glass panels. This can be done by using gaskets covered by rail tops or a U-profile to avoid direct contact of the moisture with the interlayers. B By using the interlayers Saflex DG41 or Sentry Plus instead of the traditional PVB's. Those structural interlayers, 100 X stiffer than the traditional PVB's don't take moisture which avoids the risk of delamination. |

|